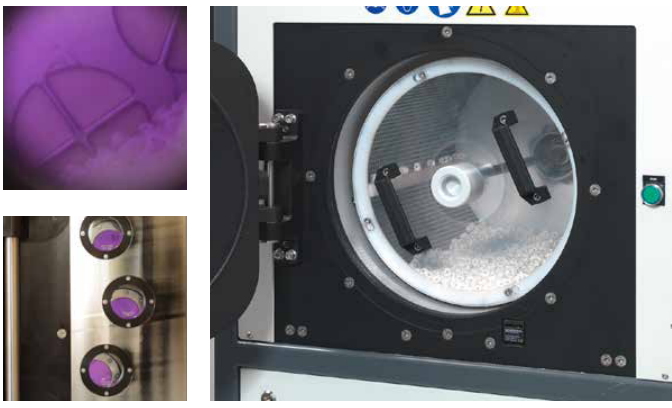

Treating Machine

RotoVAC

product features:

|

·Easy to install and use ·Short processing time ·Standard or customized processing bins ·Degree of vacuum ·No process gas required ·Control process ·save costs ·Plasma treatment under vacuum |

|

Standard and customized vacuum plasma processing equipment

Tantec's RotoVAC plasma processing equipment is used to process small injection molded parts without the need to place it on a stand or use a complex handling mechanism. RotoTEC uses a rotating barrel design. The processed product is placed in the barrel, and the barrel is placed in a vacuum chamber and rotated to uniformly treat all surfaces of the product.

Before the plasma electrode is discharged, a vacuum of 1 to 4 mbar will appear in the processing chamber, so the processing time is very short. According to the material and structure of the product, it is generally between 20-180s.

RotoVAC plasma processing equipment has the characteristics of simple operation, high production reliability and fast processing speed. Process gases such as argon or oxygen can be used, but in most cases, the high energy generated by plasma discharge can greatly increase the surface energy of objects, so there is no need to use these process gases.

RotoVAC uses advanced HV-X series discharge generators. Plasma transformers are designed based on the electrodes and provide them with high voltage. The rotation of the drum ensures that each product is processed. Another barrel can be equipped for alternate use.

Features:

·Simple installation and easy use Simply connect the power supply and compressed air.

·Short processing time According to the material and structure of the product, it can be completed within 20-180s.

·Standard or customized processing bins The sizes of the processing bins and drums can be designed according to the actual application, and are generally standard processing bins.

·Vacuum degree According to the actual application, the vacuum degree is generally 1-4mbar.

·No process gas required Process gases such as oxygen and argon can be used, but in most cases they are not required.

·Control process The entire plasma process is controlled by the HV-X series discharge generator and PLC device. All control parameters are displayed on the touch panel (standard-proface)

·Cost saving Due to low energy consumption and no special process gas required, this set of equipment greatly saves costs and is the best way to improve the surface wettability and adhesion of objects.

·Plasma treatment under vacuum treats both conductive and non-conductive surfaces.

- Prev: SpinTEC

- Next ProfileTECEPDM