Treating Machine

VacuLINE

product features:

|

· Easy to install and use · Fast processing speed · Standard / customized cavity · Gas control in process · Process monitoring · save costs · Vacuum plasma · Automated processing |

|

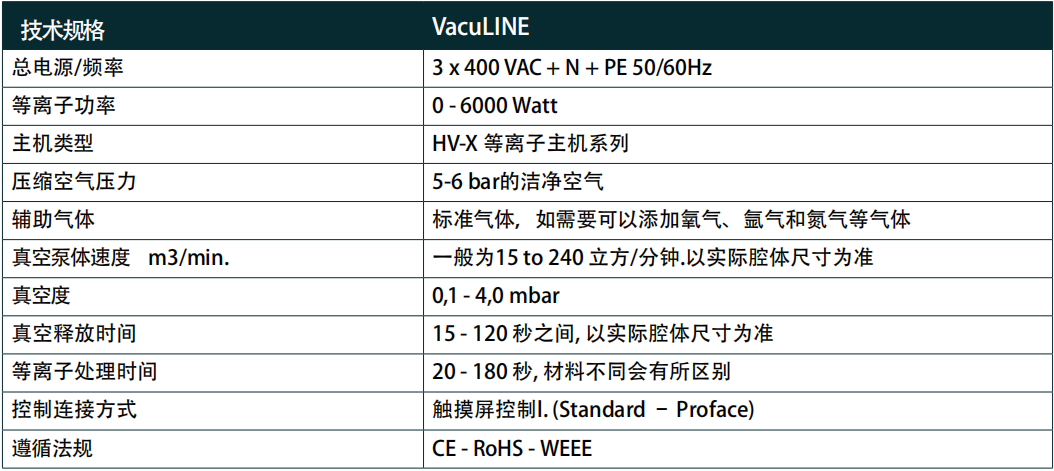

VacuLINE online vacuum plasma equipment is an online processing equipment that can be applied to different injection mold products. The equipment realizes that the entire processing process does not require human operation, and the rapid processing process of the equipment provides the best product surface energy and good combination for the layers, glue, printing, and spraying of downstream processes.

The vacuum cavity of the device and intelligent integrated plasma electrode are combined to realize the precise discharge of the plasma in the state of 0.1-0.4Mbar. At the same time, the processing time is very short. In general, there are different combinations for different materials. The processing time is generally controlled. Around 20-180 seconds.

VacuLINE vacuum plasma processing line has the advantages of simple operation, reliable production and fast processing speed. Auxiliary gases such as argon and oxygen can be added during the process to improve the surface treatment effect, but in most cases, because high-power plasma discharge generally does not require gas to assist in participation.

VacuLINE uses the advanced Tantec host group HV-X series as the power supply, and the specially designed high-frequency high-voltage transformer provides powerful power output for the plasma electrode.

Features:

·Low-cost processing technology can improve the wettability and adhesion of the material surface with almost no auxiliary gas.

·Fast processing speed Efficient output power can achieve different materials can be processed quickly in 20-180 seconds.

·Treatment of different materials It can realize the treatment of any materials such as insulating materials and non-insulating materials.

·Auxiliary gas During the process, auxiliary gases such as argon, oxygen, and nitrogen can be added, but they are generally not required.

·Easy installation Just connect power and compressed air.

·Process monitoring The HV-X host and PLC monitor the entire process in real time. All parameters are displayed on the touch screen.

·Easy maintenance This equipment is easy to install, easy to operate and easy to maintain.

·Standard / customized cavity The vacuum processing cavity can be customized according to the different requirements of customers.

·全自動線體 與機械手或運輸線組合集成簡單便捷。